The following two links will get you two outstanding organizations to provide direct help for Haiti.

Our main intention of being here is to preserve, introduce, and re-populate the land with all kinds of fruiting/beneficial trees, to promote breeding and exchanging seeds, to show that Haiti can produce valuable products in a sustainable way without clear cutting and deforestation and to create an educational and retreat center where people from all over the world can come visit and learn about the community here and what is happening first hand.

Trees are a precious resource. They provide us with cleaner air, oxygen, food, medicine, prevents water pollution, conserves energy, prevents soil erosion, and many more. Trees can also provide lumber and firewood if done sustainably but remember to replant multiples for every tree that is cut.

Trees are a precious resource. They provide us with cleaner air, oxygen, food, medicine, prevents water pollution, conserves energy, prevents soil erosion, and many more. Trees can also provide lumber and firewood if done sustainably but remember to replant multiples for every tree that is cut.

WHY SUPPORT REFORESTATION IN HAITI?

Like many islands in the Caribbean, the country of Haiti has experienced an alarming rate of deforestation in the past 20 years. Today, much of Haiti's natural rain forests are threatened by deforestation. Charcoal production remains the number one cause of deforestation in Haiti and has turned mountains once rich in lush forest and fertile soil into barren desert land. Deforestation not only dries the land, making it extremely hard to farm for locals, but also magnifies the effects of heavy rains causing landslides and damage to river banks. Reforestation efforts are important because trees help reduce heavy rain runoff, lower the risk of erosion, reduce our carbon footprint, control the effects of floods, regulate the temperature, and provide habitats for valuable species.

Could HEMP be a good choice to be grown in HAITI?

Hemp, or industrial hemp (from Old English hænep),[1] typically found in the northern hemisphere, is a variety of the Cannabis sativa plant species that is grown specifically for the industrial uses of its derived products.[2] It is one of the fastest growing plants[3] and was one of the first plants to be spun into usable fiber 10,000 years ago.[4] It can be refined into a variety of commercial items including paper, textiles, clothing, biodegradable plastics, paint, insulation, biofuel, food, and animal feed.[5]

Although cannabis as a drug and industrial hemp both derive from the species Cannabis sativa and contain the psychoactive component tetrahydrocannabinol (THC), they are distinct strains with unique phytochemical compositions and uses.[6] Hemp has lower concentrations of THC and higher concentrations of cannabidiol (CBD), which decreases or eliminates its psychoactive effects.[6] The legality of industrial hemp varies widely between countries. Some governments regulate the concentration of THC and permit only hemp that is bred with an especially low THC content.[7][8]

Contents

Etymology[edit]

The etymology is uncertain but there appears to be no common Proto-Indo-European source for the various forms of the word; the Greek term kánnabis is the oldest attested form, which may have been borrowed from an earlier Scythian or Thracian word.[9][10] Then it appears to have been borrowed into Latin, and separately into Slavic and from there into Baltic, Finnish, and Germanic languages.[11] Following Grimm's law, the "k" would have changed to "h" with the first Germanic sound shift,[9][12] after which it may have been adapted into the Old English form, hænep. However, this theory assumes that hemp was not widely spread among different societies until after it was already being used as a psychoactive drug, which Adams and Mallory (1997) believe to be unlikely based on archaeological evidence.[9] Barber (1991) however, argued that the spread of the name "kannabis" was due to its historically more recent drug use, starting from the south, around Iran, whereas non-THC varieties of hemp are older and prehistoric.[11] Another possible source of origin is Assyrian qunnabu, which was the name for a source of oil, fiber, and medicine in the 1st millennium BC.[11]

Cognates of hemp in other Germanic languages include Dutch hennep, Danish and Norwegian hamp, German Hanf, and Swedish hampa.[9]

Uses[edit]

Hemp is used to make a variety of commercial and industrial products including rope, textiles, clothing, shoes, food, paper, bioplastics, insulation, and biofuel.[5] The bast fibers can be used to make textiles that are 100% hemp, but they are commonly blended with other fibers, such as flax, cotton or silk, as well as virgin and recycled polyester, to make woven fabrics for apparel and furnishings. The inner two fibers of the plant are more woody and typically have industrial applications, such as mulch, animal bedding and litter. When oxidized (often erroneously referred to as "drying"), hemp oil from the seeds becomes solid and can be used in the manufacture of oil-based paints, in creams as a moisturizing agent, for cooking, and in plastics. Hemp seeds have been used in bird feed mix as well.[13] A survey in 2003 showed that more than 95% of hemp seed sold in the European Union was used in animal and bird feed.[14]

Food[edit]

| Nutritional value per 100 g (3.5 oz) | |

|---|---|

| Energy | 2,451 kJ (586 kcal) |

4.67 g

| |

| Sugars | 1.50 g

0.07 g

|

| Dietary fiber | 4.0 g |

48.75 g

| |

| Saturated | 4.600 g |

| Trans | 0 g |

| Monounsaturated | 5.400 g |

| Polyunsaturated | 38.100 g

9.301 g

28.698 g

|

31.56 g

| |

| Tryptophan | 0.369 g |

| Threonine | 1.269 g |

| Isoleucine | 1.286 g |

| Leucine | 2.163 g |

| Lysine | 1.276 g |

| Methionine | 0.933 g |

| Cystine | 0.672 g |

| Phenylalanine | 1.447 g |

| Tyrosine | 1.263 g |

| Valine | 1.777 g |

| Arginine | 4.550 g |

| Histidine | 0.969 g |

| Alanine | 1.528 g |

| Aspartic acid | 3.662 g |

| Glutamic acid | 6.269 g |

| Glycine | 1.611 g |

| Proline | 1.597 g |

| Serine | 1.713 g |

| Vitamins | Quantity%DV† |

| Vitamin A equiv. |

0%

1 μg

0%

7 μg |

| Vitamin A | 11 IU |

| Thiamine (B1) |

111%

1.275 mg |

| Riboflavin (B2) |

24%

0.285 mg |

| Niacin (B3) |

61%

9.200 mg |

| Vitamin B6 |

46%

0.600 mg |

| Folate (B9) |

28%

110 μg |

| Vitamin B12 |

0%

0 μg |

| Vitamin C |

1%

0.5 mg |

| Vitamin E |

5%

0.80 mg |

| Minerals | Quantity%DV† |

| Calcium |

7%

70 mg |

| Copper |

80%

1.600 mg |

| Iron |

61%

7.95 mg |

| Magnesium |

197%

700 mg |

| Manganese |

362%

7.600 mg |

| Phosphorus |

236%

1650 mg |

| Potassium |

26%

1200 mg |

| Sodium |

0%

5 mg |

| Zinc |

104%

9.90 mg |

| Other constituents | Quantity |

| Water | 4.96 g |

| Cholesterol | 0 mg |

| |

| †Percentages are roughly approximated using US recommendations for adults. | |

Hemp seeds can be eaten raw, ground into hemp meal, sprouted or made into dried sprout powder. Hemp seeds can also be made into a liquid and used for baking or for beverages such as hemp milk and tisanes.[15] Hemp oil is cold-pressed from the seed and is high in unsaturated fatty acids.[16] The leaves of the hemp plant, while not as nutritional as the seeds, are edible and can be consumed raw as leafy vegetables in salads, and pressed to make juice.[17]

In 2011, the U.S. imported $11.5 million worth of hemp products, mostly driven by growth in the demand for hemp seed and hemp oil for use as ingredients in foods such as granola.[18]

In the UK, the Department for Environment, Food and Rural Affairs treats hemp as a purely non-food crop, but with proper licensing and proof of less than 0.2% THC concentration, hemp seeds can be imported for sowing or for sale as a food or food ingredient.[19] In the U.S., imported hemp can be used legally in food products and, as of 2000, was typically sold in health food stores or through mail order.[16]

Nutrition[edit]

A 100-gram portion of hulled hemp seeds supplies 586 calories. They contain 5% water, 5% carbohydrates, 49% total fat, and 31% protein. Hemp seeds are notable in providing 64% of the Daily Value (DV) of protein per 100-gram serving.[20] Hemp seeds are a rich source of dietary fiber (20% DV), B vitamins, and the dietary minerals manganese (362% DV), phosphorus (236% DV), magnesium (197% DV), zinc (104% DV), and iron (61% DV). About 73% of the energy in hempseed is in the form of fats and essential fatty acids,[20] mainly polyunsaturated fatty acids, linoleic, oleic, and alpha-linolenic acids.[21]

Hempseed's amino acid profile is comparable to other sources of protein such as meat, milk, eggs and soy.[21] Protein digestibility-corrected amino acid scores (PDCAAS), which attempt to measure the degree to which a food for humans is a "complete protein", were 0.49–0.53 for whole hemp seed, 0.46–0.51 for hempseed meal, and 0.63–0.66 for hulled hempseed.[22]

Storage[edit]

Hemp oil oxidizes and turns rancid within a short period of time if not stored properly;[16] its shelf life is extended when it is stored in a dark airtight container and refrigerated. Both light and heat can degrade hemp oil. [23]

Fiber[edit]

Hemp fiber has been used extensively throughout history, with production climaxing soon after being introduced to the New World. For centuries, items ranging from rope, to fabrics, to industrial materials were made from hemp fiber. Hemp was also commonly used to make sail canvas. The word "canvas" is derived from the word cannabis.[24][25] Pure hemp has a texture similar to linen.[26] Because of its versatility for use in a variety of products, today hemp is used in a number of consumer goods, including clothing, shoes, accessories, dog collars, and home wares.

Building material[edit]

Concrete-like blocks made with hemp and lime have been used as an insulating material for construction. Such blocks are not strong enough to be used for structural elements; they must be supported by a brick, wood, or steel frame.[27] However, hemp fibres are extremely strong and durable, and have been shown to be usable as a replacement for wood for many jobs, including creating very durable and breathable homes. The most common use of hemp lime in building is by casting the hemp and lime mix while wet around a timber frame with temporary shuttering, and tamping the mix to form a firm mass; after the removal of the temporary shuttering, the solidified hemp mix is then ready to be plastered with a lime plaster.[28]

The first example of the use of hempcrete was in 1986 in France with the renovation of the Maison de la Turquie in Nogent-sur-Seine by the innovator Charles Rasetti.[29] In the UK hemp lime was first used in 2000 for the construction of two test dwellings in Haverhill.[30]Designed by Modece Architects,[31] who pioneered hemp's use in UK construction, the hemp houses were monitored in comparison with other standard dwellings by BRE. Completed in 2009, the Renewable House is one of the most technologically advanced made from hemp-based materials.[32] The first US home made of hemp-based materials was completed in August 2010 in Asheville, North Carolina.[33]

A panellized system of hemp-lime panels for use in building construction is currently under test in a European Union-funded research collaboration led by the University of Bath. The panels are being designed to assure high-quality construction, rapid on-site erection, optimal hygrothermal performance from day one, and energy- and resource-efficient buildings. The 36-month-long work programme aims to refine product and manufacturing protocols, produce data for certification and marketing, warranty, insurance cover, and availability of finance. It also includes the development of markets in Britain, France, and Spain.[34]

Hemp is used as an internal plaster and is a mixture of hemp hurd (shive) mixed with larger proportions of a lime-based binder. Hemp plaster has insulative qualities.[35]

Plastic and composite materials[edit]

A mixture of fiberglass, hemp fiber, kenaf, and flax has been used since 2002 to make composite panels for automobiles.[36] The choice of which bast fiber to use is primarily based on cost and availability. Various car makers are beginning to use hemp in their cars, including Audi, BMW, Ford, GM, Chrysler, Honda, Iveco, Lotus, Mercedes, Mitsubishi, Porsche, Saturn, Volkswagen[37] and Volvo. For example, the Lotus Eco Elise[38] and the Mercedes C-Class both contain hemp (up to 20 kg in each car in the case of the latter).[39]

Paper[edit]

Hemp paper are paper varieties consisting exclusively or to a large extent from pulp obtained from fibers of industrial hemp. The products are mainly specialty papers such as cigarette paper[40], banknotes and technical filter papers[41] . Compared to wood pulp, hemp pulp offers a four to five times longer fibre, a significantly lower lignin fraction as well as a higher tear resistance and tensile strength. However, production costs are about four times higher than for paper from wood[42], so hemp paper could not be used for mass applications as printing, writing and packaging paper.

Jewelry[edit]

Hemp jewelry is the product of knotting hemp twine through the practice of macramé. Hemp jewellery includes bracelets, necklaces, anklets, rings, watches and other adornments. Some jewellery features beads made from crystals, glass, stone, wood and bones. The hemp twine varies in thickness and comes in a variety of colors. There are many different stitches used to create hemp jewellery, however, the half knot and full knot stitches are most common.

Shoes[edit]

In recent years, hemp has been growing in popularity as a material used in shoes. Today you can find boots, athletic shoes, sandals, and dress shoes that are made with 100% hemp fiber, or textiles that blend hemp fibers with materials such as cotton, jute, virgin polyester, and recycled polyester. The strength of hemp fibers makes it an ideal material for shoes because it's durable. In addition, it's breathable and naturally antimicrobial, so it doesn't hold on to odors.[43] Because hemp can be grown sustainably, shoes, clothing, and accessories made with hemp are representative of the sustainable fashion movement.

Cordage[edit]

Hemp rope was used in the age of sailing ships, though the rope had to be protected by tarring, since hemp rope has a propensity for breaking from rot, as the capillary effect of the rope-woven fibers tended to hold liquid at the interior, while seeming dry from the outside.[44] Tarring was a labor-intensive process, and earned sailors the nickname "Jack Tar". Hemp rope was phased out when Manila, which does not require tarring, became widely available. Manila is sometimes referred to as Manila hemp, but is not related to hemp; it is abacá, a species of banana.

Animal bedding[edit]

Hemp shives are the core of the stem, hemp hurds are broken parts of the core. In the EU, they are used for animal bedding (horses, for instance), or for horticultural mulch.[45] Industrial hemp is much more profitable if both fibers and shives (or even seeds) can be used.

Water and soil purification[edit]

Hemp can be used as a "mop crop" to clear impurities out of wastewater, such as sewage effluent, excessive phosphorus from chicken litter, or other unwanted substances or chemicals. Additionally, hemp is being used to clean contaminants at the Chernobyl nuclear disaster site, by way of a process which is known as phytoremediation—the process of clearing radioisotopes and a variety of other toxins from the soil, water, and air.[46]

Weed control[edit]

Hemp crops are tall, have thick foliage, and can be planted densely, and thus can be grown as a smother crop to kill tough weeds.[47] Using hemp this way can help farmers avoid the use of herbicides, gain organic certification, and gain the benefits of crop rotation. However, due to the plant's rapid and dense growth characteristics, some jurisdictions consider hemp a prohibited and noxious weed, much like Scotch Broom.[citation needed]

Biofuels[edit]

Biodiesel can be made from the oils in hemp seeds and stalks; this product is sometimes called "hempoline".[48] Alcohol fuel (ethanol or, less commonly, methanol) can be made by fermenting the whole plant.

Filtered hemp oil can be used directly to power diesel engines. In 1892, Rudolf Diesel invented the diesel engine, which he intended to power "by a variety of fuels, especially vegetable and seed oils, which earlier were used for oil lamps, i.e. the Argand lamp."[49][50][51]

Production of vehicle fuel from hemp is very small. Commercial biodiesel and biogas is typically produced from cereals, coconuts, palmseeds and cheaper raw materials like garbage, wastewater, dead plant and animal material, animal feces and kitchen waste.[52]

Processing[edit]

Traditionally, hemp stalks would be water-retted first before the fibers were beaten off the inner hurd by hand, a process known as scutching. As mechanical technology evolved, separating the fiber from the core was accomplished by crushing rollers and brush rollers that would produce a nearly clean fiber. After the Marijuana Tax Act was implemented in 1938, the technology for separating the fibers from the core remained "frozen in time".

Only in 1997, did Ireland, parts of the Commonwealth and other countries begin to legally grow industrial hemp again. Iterations of the 1930s decorticator have been met with limited success, along with steam explosion and chemical processing known as thermomechanical pulping.[citation needed]

Cultivation[edit]

This section needs additional citations for verification. (April 2018) (Learn how and when to remove this template message)

|

Hemp is usually planted between March and May in the northern hemisphere, between September and November in the southern hemisphere.[53] It matures in about three to four months.

Millennia of selective breeding have resulted in varieties that display a wide range of traits; e.g. suited for a particular environments/latitudes, producing different ratios and compositions of terpenoids and cannabinoids (CBD, THC, CBG, CBC, CBN...etc.), fibre quality, oil/seed yield etc. Hemp grown for fiber is planted closely, resulting in tall, slender plants with long fibers.

Use of industrial hemp plant and its cultivation was commonplace until the 1900s, when it was associated with its genetic sibling aka Drug-Type Cannabis species (which contain higher levels of psychoactive THC). Influential groups misconstrued hemp as a dangerous 'drug', even though it is not a 'drug' and it has the potential to be a sustainable & profitable alternative crop.

In the United States, the public's perception of hemp as marijuana has blocked hemp from becoming a useful crop and product,"[54] in spite of its vital importance prior to World War II.[55] Ideally, according to Britain's Department for Environment, Food and Rural Affairs, the herb should be desiccated and harvested towards the end of flowering. This early cropping reduces the seed yield but improves the fiber yield and quality.[56] In these strains of industrial hemp* the tetrahydrocannabinol (THC) content would have been very low.[54]

The seeds are sown from mid-April to mid-May with grain drills to 4–6 cm sowing depth. Hemp needs less fertilizer than corn does. A total of 60–150 kg of nitrogen, 40–140 kg phosphorus (P2O5) and 75–200 kg of potassium [5] per acre for hemp fiber made before sowing and again later, maybe three to four weeks. When practiced, especially in France double use of fiber and seed fertilization with nitrogen doses up to 100 kg / ha rather low. Organic fertilizers such as manure can utilize industrial hemp well. Neither weeds nor crop protection measures are necessary.[54]

Cultivars[edit]

In contrast to cannabis for medical use, varieties grown for fiber and seed have less than 0.3% THC and are unsuitable for producing hashish and marijuana.[57] Present in industrial hemp, cannabidiol is a major constituent among some 560 compounds found in hemp.[58]

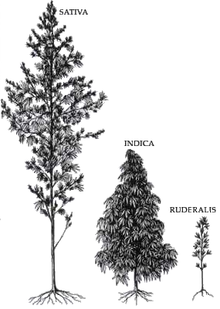

Cannabis sativa L. subsp. sativa var. sativa is the variety grown for industrial use, while C. sativa subsp. indica generally has poor fiber quality and female buds from this variety are primarily used for recreational and medicinal purposes. The major differences between the two types of plants are the appearance, and the amount of Δ9-tetrahydrocannabinol (THC) secreted in a resinous mixture by epidermal hairs called glandular trichomes, although they can also be distinguished genetically.[57][59] Oilseed and fiber varieties of Cannabis approved for industrial hemp production produce only minute amounts of this psychoactive drug, not enough for any physical or psychological effects. Typically, hemp contains below 0.3% THC, while cultivars of Cannabis grown for medicinal or recreational use can contain anywhere from 2% to over 20%.[60]

Harvesting[edit]

Smallholder plots are usually harvested by hand. The plants are cut at 2 to 3 cm above the soil and left on the ground to dry. Mechanical harvesting is now common, using specially adapted cutter-binders or simpler cutters.

The cut hemp is laid in swathes to dry for up to four days. This was traditionally followed by retting, either water retting (the bundled hemp floats in water) or dew retting (the hemp remains on the ground and is affected by the moisture in dew, and by molds and bacterialaction).

Location and crop rotation[edit]

For profitable hemp farming, particularly deep, humus-rich, nutrient-rich soil with controlled water flow is preferable. Waterlogged acidic, compressed or extremely light (sandy) soils primarily affect the early development of plants.[citation needed] Steep and high altitudes of more than 400 m above sea level are best avoided. Hemp is relatively insensitive to cold temperatures and can withstand frost down to −5 °C.[citation needed] Seeds can germinate down to 1–3 °C.[citation needed] Hemp needs a lot of heat, so earlier varieties come to maturation. The water requirement is 300–500 l/kg dry matter.[citation needed] This is around 1/14th that of cotton, which takes between 7,000 and 29,000 l/kg, according to WWF.[citation needed] Roots can grow up to 3 feet into the soil and use water from deeper soil layers.

Hemp benefits crops grown after it. So, it is generally grown before winter cereals. Advantageous changes are high weed suppression, soil loosening by the large hemp root system, and the positive effect on soil tilth. Since hemp is very self-compatible, it can also be grown several years in a row in the same fields (monoculture).

Diseases[edit]

Hemp plants can be vulnerable to various pathogens, including bacteria, fungi, nematodes, viruses and other miscellaneous pathogens. Such diseases often lead to reduced fiber quality, stunted growth, and death of the plant. These diseases rarely affect the yield of a hemp field, so hemp production is not traditionally dependent on the use of pesticides.

Environmental impact[edit]

Hemp is considered by a 1998 study in Environmental Economics to be environmentally friendly due to a decrease of land use and other environmental impacts, indicating a possible decrease of ecological footprint in a US context compared to typical benchmarks.[61] A 2010 study, however, that compared the production of paper specifically from hemp and eucalyptus concluded that "industrial hemp presents higher environmental impacts than eucalyptus paper"; however, the article also highlights that "there is scope for improving industrial hemp paper production".[62] Hemp is also claimed to require few pesticides and no herbicides, and it has been called a carbon negative raw material.[63][64] Results indicate that high yield of hemp may require high total nutrient levels (field plus fertilizer nutrients) similar to a high yielding wheat crop.[65]

Producers[edit]

The world-leading producer of hemp is China, which produces more than 70% of the world output. France ranks second with about a quarter of the world production. Smaller production occurs in the rest of Europe, Chile, and North Korea. Over 30 countries produce industrial hemp, including Australia, Austria, Canada, Chile, China, Denmark, Egypt, Finland, Great Britain, Germany, Greece,[66] Hungary, India, Italy, Japan, Korea, Netherlands, New Zealand, Poland, Portugal, Romania, Russia, Slovenia, Spain, Sweden, Switzerland, Thailand, Turkey and Ukraine.[67][68]

The United Kingdom and Germany resumed commercial production in the 1990s. British production is mostly used as bedding for horses; other uses are under development. Companies in Canada, the UK, the United States, and Germany, among many others, process hemp seed into a growing range of food products and cosmetics; many traditional growing countries still continue to produce textile-grade fibre.

Air-dried stem yields in Ontario have from 1998 and onward ranged from 2.6-14.0 tonnes of dry, retted stalks per hectare (1-5.5 t/ac) at 12% moisture. Yields in Kent County, have averaged 8.75 t/ha (3.5 t/ac). Northern Ontario crops averaged 6.1 t/ha (2.5 t/ac) in 1998. Statistic for the European Union for 2008 to 2010 say that the average yield of hemp straw has varied between 6.3 and 7.3 ton per ha.[69][70] Only a part of that is bast fiber. Around one tonne of bast fiber and 2-3 tonnes of core material can be decorticated from 3-4 tonnes of good-quality, dry-retted straw. For an annual yield of this level is it in Ontario recommended to add nitrogen (N):70–110 kg/ha, phosphate(P2O5): up to 80 kg/ha and potash (K2O): 40–90 kg/ha.[71] The average yield of dry hemp stalks in Europe was 6 ton/ha (2.4 ton/ac) in 2001 and 2002.[14]

FAO argue that an optimum yield of hemp fiber is more than 2 tonnes per ha, while average yields are around 650 kg/ha.[72]

Australia[edit]

In the Australian states of Tasmania, Victoria, Queensland, New South Wales, and most recently, South Australia, the state governments have issued licences to grow hemp for industrial use. The first to initiate modern research into the potential of cannabis was the state of Tasmania, which pioneered the licensing of hemp during the early 1990s. The state of Victoria was an early adopter in 1998, and has reissued the regulation in 2008.[73]

Queensland has allowed industrial production under licence since 2002,[74] where the issuance is controlled under the Drugs Misuse Act 1986.[75] New South Wales now issues licences[76] under a law, the Hemp Industry Regulations Act 2008 (No 58), that came into effect as of 6 November 2008.[77] Most recently, South Wales legalized industrial hemp under South Australia’s Industrial Hemp Act 2017, which commenced on 12 November 2017.[78]

Canada[edit]

Commercial production (including cultivation) of industrial hemp has been permitted in Canada since 1998 under licenses and authorization issued by Health Canada (9,725 ha in 2004, 5450 ha in 2009).[79]

In the early 1990s, industrial hemp agriculture in North America began with the Hemp Awareness Committee at the University of Manitoba. The Committee worked with the provincial government to get research and development assistance, and was able to obtain test plot permits from the Canadian government. Their efforts led to the legalization of industrial hemp (hemp with only minute amounts of tetrahydrocannabinol) in Canada and the first harvest in 1998.[80][81]

In 2017, the cultivated area for hemp in the Prairie provinces include Saskatchewan with more than 56,000 acres (23,000 ha), Alberta with 45,000 acres (18,000 ha), and Manitoba with 30,000 acres (12,000 ha).[82] Canadian hemp is cultivated mostly for its food value as hulled hemp seeds, hemp oils and hemp protein powders, with only a small fraction devoted to production of hemp fiber used for construction and insulation.[82]

France[edit]

France is Europe's biggest producer (and the world's second largest producer) with 8,000 hectares cultivated.[83] 70-80% of the hemp fibre produced in 2003 was used for specialty pulp for cigarette papers and technical applications. About 15% was used in the automotive sector, and 5-6% was used for insulation mats. About 95% of hurds were used as animal bedding, while almost 5% was used in the building sector.[14] In 2010/2011, a total of 11,000 hectares (27,000 acres) was cultivated with hemp in the EU, a decline compared with previous year.[70][84]

Russia and Ukraine[edit]

From the 1950s to the 1980s, the Soviet Union was the world's largest producer of hemp (3,000 km2 in 1970). The main production areas were in Ukraine,[85] the Kursk and Orel regions of Russia, and near the Polish border. Since its inception in 1931, the Hemp Breeding Department at the Institute of Bast Crops in Hlukhiv (Glukhov), Ukraine, has been one of the world's largest centers for developing new hemp varieties, focusing on improving fiber quality, per-hectare yields, and low THC content.[86][87]

After the collapse of the Soviet Union, the commercial cultivation of hemp declined sharply. However, at least an estimated 2.5 million acres of hemp grow wild in the Russian Far East and Black Sea regions.[88]

United Kingdom[edit]

In the United Kingdom, cultivation licences are issued by the Home Office under the Misuse of Drugs Act 1971. When grown for nondrug purposes, hemp is referred to as industrial hemp, and a common product is fibre for use in a wide variety of products, as well as the seed for nutritional aspects and for the oil. Feral hemp or ditch weed is usually a naturalized fibre or oilseed strain of Cannabis that has escaped from cultivation and is self-seeding.[89]

United States[edit]

Hemp was made illegal to grow without a permit in the U.S. under the Controlled Substances Act passed in 1970 because of its relation to marijuana,[18] and any imported hemp products must meet a zero tolerance level.[90] Some states have made the cultivation of industrial hemp legal, but farmers in many states have not yet begun to grow it because of resistance from the federal Drug Enforcement Administration,[91] making "large-scale hemp growing" in the United States "not viable" as late as 2013.[92] In 2013, after the legalization of cannabis in the state, several farmers in Colorado planted and harvested several acres of hemp, bringing in the first hemp crop in the United States in over half a century.[93] Colorado,[94] Vermont, California, and North Dakota have passed laws enabling hemp licensure. All four states are waiting for permission to grow hemp from the DEA. Currently,[95] Oregon has licensed industrial hemp as of August 2009.[96] Congress included a provision in the Agricultural Act of 2014 that allowed colleges and state agencies to grow and conduct research on hemp in states where it is legal.[18] Hemp production in Kentucky, formerly the United States' leading producer, resumed in 2014.[97] Hemp production in North Carolina resumed in 2017,[98] and in Washington State the same year.[99] By the end of 2017, at least 34 U.S. states had industrial hemp programs.[100] In 2018, New York began taking strides in industrial hemp production, along with hemp research pilot programs at Cornell University, Binghamton University and SUNY Morrisville.[101]

As of 2015 the hemp industry estimated that annual sales of hemp products were around US$600 million annually; hemp seeds have been the major force driving this growth.[102]

Yet, even with this progress, hemp businesses seem to face difficulty expanding in the US as they face challenges in traditional marketing and sales approaches. According to a case study done by Forbes, hemp businesses and startups have had difficulty marketing and selling non-psychoactive hemp products, as some online advertising platforms and financial institutions do not distinguish between hemp and marijuana.[103]

The Hemp Farming Act of 2018, part of the 2018 Farm Bill[104] signed by President Donald Trump December 20, 2018,[105] changed hemp from a controlled substance to an agricultural commodity, which made it easier for farmers to get loans to grow hemp, and allowed them to get federal crop insurance.[104]

History[edit]

Hemp is possibly one of the earliest plants to be cultivated.[107][108] An archeological site in the Oki Islands near Japan contained cannabis achenes from about 8000 BC, probably signifying use of the plant.[109] Hemp use archaeologically dates back to the Neolithic Age in China, with hemp fiber imprints found on Yangshao culture pottery dating from the 5th millennium BC.[106][110] The Chinese later used hemp to make clothes, shoes, ropes, and an early form of paper.[106] The classical Greek historian Herodotus (ca. 480 BC) reported that the inhabitants of Scythia would often inhale the vapors of hemp-seed smoke, both as ritual and for their own pleasurable recreation.[111]

Textile expert Elizabeth Wayland Barber summarizes the historical evidence that Cannabis sativa, "grew and was known in the Neolithic period all across the northern latitudes, from Europe (Germany, Switzerland, Austria, Romania, Ukraine) to East Asia (Tibet and China)," but, "textile use of Cannabis sativa does not surface for certain in the West until relatively late, namely the Iron Age."[112] "I strongly suspect, however, that what catapulted hemp to sudden fame and fortune as a cultigen and caused it to spread rapidly westwards in the first millennium B.C. was the spread of the habit of pot-smoking from somewhere in south-central Asia, where the drug-bearing variety of the plant originally occurred. The linguistic evidence strongly supports this theory, both as to time and direction of spread and as to cause."[113]

Jews living in Palestine in the 2nd century were familiar with the cultivation of hemp, as witnessed by a reference to it in the Mishna (Kil'ayim 2:5) as a variety of plant, along with Arum, that sometimes takes as many as three years to grow from a seedling. In late medieval Germany and Italy, hemp was employed in cooked dishes, as filling in pies and tortes, or boiled in a soup.[114] Hemp in later Europe was mainly cultivated for its fibers, and was used for ropes on many ships, including those of Christopher Columbus. The use of hemp as a cloth was centered largely in the countryside, with higher quality textiles being available in the towns.

The Spaniards brought hemp to the Americas and cultivated it in Chile starting about 1545.[115] Similar attempts were made in Peru, Colombia, and Mexico, but only in Chile did the crop find success.[116] In July 1605, Samuel Champlain reported the use of grass and hemp clothing by the (Wampanoag) people of Cape Cod and the (Nauset) people of Plymouth Bay told him they harvested hemp in their region where it grew wild to a height of 4 to 5 ft. [117] In May 1607, "hempe" was among the crops Gabriel Archer observed being cultivated by the natives at the main Powhatan village, where Richmond, Virginia is now situated;[118] and in 1613, Samuell Argall reported wild hemp "better than that in England" growing along the shores of the upper Potomac. As early as 1619, the first Virginia House of Burgesses passed an Act requiring all planters in Virginia to sow "both English and Indian" hemp on their plantations.[119] The Puritans are first known to have cultivated hemp in New England in 1645.[115]

United States[edit]

George Washington pushed for the growth of hemp and even grew hemp himself, as it was a cash crop commonly used to make rope and fabric. In May 1765 he noted in his diary about the sowing of seeds each day until mid-April. Then he recounts the harvest in October which he grew 27 bushels that year.

There is some speculation that George Washington smoked the flower of the cannabis plant in order to achieve a recreational high ("Like all farmers, Washington probably sampled the quality and potency of what he grew, and he may have used this hemp to treat his chronic tooth aches"),[55] but there is no evidence in any of his writings that he grew hemp for anything other than industrial purposes. It is sometimes supposed that an excerpt from Washington's diary, which reads "Began to seperate [sic] the Male from the Female hemp at Do.&—rather too late" is evidence that he was trying to grow female plants for the THC found in the flowers. However, the editorial remark accompanying the diary states that "This may arise from their [the male] being coarser, and the stalks larger"[120] In subsequent days, he describes soaking the hemp[121] (to make the fibers usable) and harvesting the seeds,[122] suggesting that he was growing hemp for industrial purposes, not recreational.

George Washington also imported the Indian Hemp plant from Asia, which was used for fiber and, by some growers, for intoxicating resin production. In a letter to William Pearce who managed the plants for him Washington says, "What was done with the Indian Hemp plant from last summer? It ought, all of it, to be sown again; that not only a stock of seed sufficient for my own purposes might have been raised, but to have disseminated seed to others; as it is more valuable than common hemp."[citation needed]

Additional presidents known to have farmed hemp include Thomas Jefferson,[123] James Madison, James Monroe, Andrew Jackson, Zachary Taylor, and Franklin Pierce. [124]

Historically, hemp production had made up a significant portion of antebellum Kentucky's economy. Before the American Civil War, many slaves worked on plantations producing hemp.[125]

In 1937, the Marihuana Tax Act of 1937 was passed in the United States, levying a tax on anyone who dealt commercially in cannabis, hemp, or marijuana. The passing of the Act to destroy the US hemp industry has been disputed to involve businessmen Andrew Mellon, Randolph Hearst and the Du Pont family.[126][127][128]

One claim is that Hearst believed[dubious ] that his extensive timber holdings were threatened by the invention of the decorticator which he feared would allow hemp to become a cheap substitute for the paper pulp used for newspaper.[126][129] Historical research indicates this fear was unfounded because improvements of the decorticators in the 1930s – machines that separated the fibers from the hemp stem – could not make hemp fiber a cheaper substitute for fibers from other sources. Further, decorticators did not perform satisfactorily in commercial production.[130][126]

Another claim is that Mellon, Secretary of the Treasury and the wealthiest man in America at that time, had invested heavily in DuPont's new synthetic fiber, nylon, and believed[dubious ] that the replacement of the traditional resource, hemp, was integral to the new product's success.[126][131][132][133][134][135][136][137] The company DuPont and many industrial historians dispute a link between nylon and hemp, nylon became immediately a scarce commodity.[clarification needed] Nylon had characteristics that could be used for toothbrushes (sold from 1938) and very thin nylon fiber could compete with silk and rayon in various textiles normally not produced from hemp fiber, such as very thin stockings for women.[130][138][139][140][141]

Hemp was used extensively by the United States during World War II to make uniforms, canvas, and rope.[142] Much of the hemp used was cultivated in Kentucky and the Midwest. During World War II, the U.S. produced a short 1942 film, Hemp for Victory, promoting hemp as a necessary crop to win the war.

- History in the United States

Historical cultivation[edit]

Hemp has been grown for millennia in Asia and the Middle East for its fibre. Commercial production of hemp in the West took off in the eighteenth century, but was grown in the sixteenth century in eastern England.[145] Because of colonial and naval expansion of the era, economies needed large quantities of hemp for rope and oakum. In the early 1940s, world production of hemp fiber ranged from 250 000 to 350 000 metric tonnes, Russia was the biggest producer.[130]

In Western Europe, the cultivation of hemp was not legally banned by the 1930s, but the commercial cultivation stopped by then, due to decreased demand compared to increasingly popular artificial fibers.[146] Speculation about the potential for commercial cultivation of hemp in large quantities has been criticized due to successful competition from other fibers for many products. The world production of hemp fiber fell from over 300,000 metric tons 1961 to about 75,000 metric tons in the early 1990s and has after that been stable at that level.[147]

Japan[edit]

In Japan, hemp was historically used as paper and a fiber crop. There is archaeological evidence cannabis was used for clothing and the seeds were eaten in Japan back to the Jōmon period (10,000 to 300 BC). Many Kimonodesigns portray hemp, or asa (Japanese: 麻), as a beautiful plant. In 1948, marijuana was restricted as a narcotic drug. The ban on marijuana imposed by the United States authorities was alien to Japanese culture, as the drug had never been widely used in Japan before. Though these laws against marijuana are some of the world's strictest, allowing five years imprisonment for possession of the drug, they exempt hemp growers, whose crop is used to make robes for Buddhist monks and loincloths for Sumo wrestlers. Because marijuana use in Japan has doubled in the past decade, these exemptions have recently been called into question.[148]

Portugal[edit]

The cultivation of hemp in Portuguese lands began around the fourteenth century onwards, it was raw material for the preparation of rope and plugs for the Portuguese ships. Colonies for factories for the production of flax hemp, such as the Royal Flax Hemp Factory in Brazil.

After the Restoration of Independence in 1640, in order to recover the ailing Portuguese naval fleet, were encouraged its cultivation as the Royal Decree of D. John IV in 1656. At that time its cultivation was carried out in Trás-os-Montes, Zone Tower Moncorvo, more precisely in Vilariça Valley, fertile land for any crop irrigation, and a very large area, flat and very fertile culture still wide until the last century grew up tobacco, a plant that needs a large space to expand and grow, the area lies in the valley of Serra de Bornes.

In 1971, the cultivation of hemp became illegal, and the production was substantially reduced. Because of EU regulations 1308/70, 619/71 and 1164/89, this law was revoked (for some certified seed varieties).[149]

See also[edit]

SOURCE

WHY was hemp banned for about 70 years and now its legal again? -Corruption and Money

INDUSTRIAL HEMP SOLUTIONS

Hemp: A New Crop with New Uses for North America*

Ernest Small and David Marcus

*This paper was considerably improved by criticism provided by A. McElroy.

“Hemp” refers primarily to Cannabis sativa L. (Cannabaceae), although the term has been applied to dozens of species representing at least 22 genera, often prominent fiber crops. For examples, Manila hemp (abaca) is Musa textilis Née, sisal hemp is Agave sisalina Perrine, and sunn hemp is Crotolaria juncea L. Especially confusing is the phrase “Indian hemp,” which has been used both for narcotic Asian land races of C. sativa (so-called C. indica Lamarck of India) and Apocynum cannabinum L., which was used by North American Indians as a fiber plant. Cannabis sativa is a multi-purpose plant that has been domesticated for bast (phloem) fiber in the stem, a multi-purpose fixed oil in the “seeds” (achenes), and an intoxicating resin secreted by epidermal glands. The common names hemp and marijuana (much less frequently spelled marihuana) have been applied loosely to all three forms, although historically hemp has been used primarily for the fiber cultigen and its fiber preparations, and marijuana for the drug cultigen and its drug preparations. The current hemp industry is making great efforts to point out that “hemp is not marijuana.” Italicized,Cannabis refers to the biological name of the plant (only one species of this genus is commonly recognized, C. sativa L.). Non-italicized, “cannabis” is a generic abstraction, widely used as a noun and adjective, and commonly (often loosely) used both for cannabis plants and/or any or all of the intoxicant preparations made from them.

Probably indigenous to temperate Asia, C. sativa is the most widely cited example of a “camp follower.” It was pre-adapted to thrive in the manured soils around man’s early settlements, which quickly led to its domestication (Schultes 1970). Hemp was harvested by the Chinese 8500 years ago (Schultes and Hofmann 1980). For most of its history, C. sativa was most valued as a fiber source, considerably less so as an intoxicant, and only to a limited extent as an oilseed crop. Hemp is one of the oldest sources of textile fiber, with extant remains of hempen cloth trailing back 6 millennia. Hemp grown for fiber was introduced to western Asia and Egypt, and subsequently to Europe somewhere between 1000 and 2000 BCE. Cultivation in Europe became widespread after 500 ce. The crop was first brought to South America in 1545, in Chile, and to North America in Port Royal, Acadia in 1606. The hemp industry flourished in Kentucky, Missouri, and Illinois between 1840 and 1860 because of the strong demand for sailcloth and cordage (Ehrensing 1998). From the end of the Civil War until 1912, virtually all hemp in the US was produced in Kentucky. During World War I, some hemp cultivation occurred in several states, including Kentucky, Wisconsin, California, North Dakota, South Dakota, Minnesota, Indiana, Illinois, Ohio, Michigan, Kansas, and Iowa (Ehrensing 1998). The second world war led to a brief revival of hemp cultivation in the Midwest, as well as in Canada, because the war cut off supplies of fiber (substantial renewed cultivation also occurred in Germany for the same reason). Until the beginning of the 19th century, hemp was the leading cordage fiber. Until the middle of the 19th century, hemp rivaled flax as the chief textile fiber of vegetable origin, and indeed was described as “the king of fiber-bearing plants,—the standard by which all other fibers are measured” (Boyce 1900). Nevertheless, the Marihuana Tax Act applied in 1938 essentially ended hemp production in the United States, although a small hemp fiber industry continued in Wisconsin until 1958. Similarly in 1938 the cultivation of Cannabis became illegal in Canada under the Opium and Narcotics Act.

Hemp, grown under license mostly in Canada, is the most publicized “new” crop in North America. Until very recently the prohibition against drug forms of the plant prevented consideration of cultivation of fiber and oilseed cultivars in Canada. However, in the last 10 years three key developments occurred: (1) much-publicized recent advances in the legal cultivation of hemp in western Europe, especially for new value-added products; (2) enterprising farmers and farm groups became convinced of the agricultural potential of hemp in Canada, and obtained permits to conduct experimental cultivation; and (3) lobby groups convinced the government of Canada that narcotic forms of the hemp plant are distinct and distinguishable from fiber and oilseed forms. In March 1998, new regulations (under the Controlled Drugs and Substances Act) were provided to allow the commercial development of a hemp industry in Canada, and since then more than a thousand licenses have been issued. Hectares licensed for cultivation for 1998–2001 were respectively, 2,500, 14,200, 5,487, and 1,355, the decreasing trend due to a glut of seed produced in 1999 and pessimism over new potential regulations barring exports to the US. Information on the commercial potential of hemp in Canada is in Blade (1998), Marcus (1998), and Pinfold Consulting (1998). In the US, a substantial trade in hemp products has developed, based on imports of hemp fiber, grain, and oil. The American agricultural community has observed this, and has had success at the state level in persuading legislators of the advisability of experimental hemp cultivation as a means of evaluating the wisdom of re-establishing American hemp production. However, because of opposition by the federal government, to date there has only been a small experimental plot in Hawaii. Information on the commercial potential of hemp in the US is presented in the following.

Cannabis sativa is extremely unusual in the diversity of products for which it is or can be cultivated. Popular Mechanics magazine (1938) touted hemp as “the new billion dollar crop,” stating that it “can be used to produce more than 25,000 products, ranging from dynamite to Cellophane.” Table 1 presents the principal products for which the species is cultivated in Europe, all of which happen to be based on fiber. This presentation stresses the products that hold the most promise for North America, which also include a considerable range of oilseed applications (Table 2; Fig. 1).

Table 1. Hemp fiber usage in the European Union in 1999 (after Karus et al. 2000).

| Class of product | Quantity consumed (tonnes) | Relative percentage |

| Specialty pulp (cigarette paper, bank notes, technical filters, and hygiene products) | 24,882 | 87 |

| Composites for autos | 1,770 | 6 |

| Construction & thermal insulation materials | 1,095 | 4 |

| Geotextiles | 234 | 0.8 |

| Other | 650 | 2.2 |

| Total | 26,821 | 100 |

| Seeds (achenes) | Long ("bark) fiber | Woody stem core | Female floral (perigonal) bract | Whole plant |

| Confectionary, baked goods | Plastic-molded products | Animal bedding | Medicinal cannabinoids | Alcohol |

| Salad oil | Specialty papers | Thermal insulation | Essential oil (for flavor & perfume) | Fuel |

| ody care "cosmetics | Construction fiberboard | Construction (fiberboard, plaster board, etc.) | Insect repellant | Silage |

| Animal food (whole seeds for birds, presscake for mammalian livestock) | Biodegradable landscape matting & plant culture products | |||

| Gamma-linolenic acid dietary supplements | Coarse textiles (carpets, upholstery) | |||

| Specialty industrial oils | Fine textiles |

Fig. 1. Major uses of industrial hemp.

BASIC CATEGORIES OF CANNABIS AND THEIR FIELD ARCHITECTURE

Cannabis sativa is an annual wind-pollinated plant, normally dioecious and dimorphic, although sometimes monoecious (mostly in several modern European fiber cultivars). Figure 2 presents the basic morphology of the species. Some special hybrids, obtained by pollinating females of dioecious lines with pollen from monoecious plants, are predominantly female (so-called “all-female,” these generally also produce some hermaphrodites and occasional males). All-female lines are productive for some purposes (e.g. they are very uniform, and with very few males to take up space they can produce considerable grain), but the hybrid seed is expensive to produce. Staminate or “male” plants tend to be 10%–15% taller and are less robust than the pistillate or “female” (note the comparatively frail male in Fig. 3). So prolific is pollen production that an isolation distance of about 5 km is usually recommended for generating pure-bred foundation seed. A “perigonal bract” subtends each female flower, and grows to envelop the fruit. While small, secretory, resin-producing glands occur on the epidermis of most of the above-ground parts of the plant, the glands are very dense and productive on the perigonal bracts, which are accordingly of central interest in marijuana varieties. The root is a laterally branched taproot, generally 30–60 cm deep, up to 2.5 m in loose soils, very near the surface and more branched in wet soils. Extensive root systems are key to the ability of hemp crops to exploit deep supplies of nutrients and water. The stems are erect, furrowed, and usually branched, with a woody interior, and may be hollow in the internodes. Although the stem is often woody, the species is frequently referred to as a herb or forb. Plants vary enormously in height depending on genetic constitution and environment (Fig. 4), but are typically 1–5 m (heights of 12 m or more in cultivation have been claimed).

Fig. 2. Cannabis sativa. This superb composite plate by artist Elmer Smith, often reproduced at a very small scale and without explanation in marijuana books, is the best scientific illustration of the hemp plant ever prepared. 1. Flowering branch of male plant. 2. Flowering branch of female plant. 3. Seedling. 4. Leaflet. 5. Cluster of male flowers. 6. Female flower, enclosed by perigonal bract. 7. Mature fruit enclosed in perigonal bract. 8. Seed (achene), showing wide face. 9. Seed, showing narrow face. 10. Stalked secretory gland. 11. Top of sessile secretory gland. 12. Long section of cystolith hair (note calcium carbonate concretion at base). Reproduced with the permission of Harvard University, Cambridge, MA.

|  |

| Fig. 3. Photograph of Cannabis sativa. Left, staminate (“male”) plant in flower; right, pistillate (“female”) plant in flower. | Fig. 4. United States National Institute of Health, University of Mississippi marijuana plantation site, showing variation in plant size. A tall fiber-type of hemp plant is shown at left, and a short narcotic variety (identified as “Panama Gold”) at right. |

Fig. 5. Typical architecture of categories of cultivated Cannabis sativa. Top left: narcotic plants are generally low, highly branched, and grown well-spaced. Top right: plants grown for oilseed were traditionally well-spaced, and the plants developed medium height and strong branching. Bottom left: fiber cultivars are grown at high density, and are unbranched and very tall. Bottom center: “dual purpose” plants are grown at moderate density, tend to be slightly branched and of medium to tall height. Bottom right: some recent oilseed cultivars are grown at moderate density and are short and relatively unbranched. Degree of branching and height are determined both by the density of the plants and their genetic background.

Highly selected forms of the fiber cultigen possess features maximizing fiber production. Since the nodes tend to disrupt the length of the fiber bundles, thereby limiting quality, tall, relatively unbranched plants with long internodes have been selected. Another strategy has been to select stems that are hollow at the internodes, with limited wood, since this maximizes production of fiber in relation to supporting woody tissues. Similarly, limited seed productivity concentrates the plant’s energy into production of fiber, and fiber cultivars often have low genetic propensity for seed output. Selecting monoecious strains overcomes the problem of differential maturation times and quality of male (staminate) and female (pistillate) plants (males mature 1–3 weeks earlier). Male plants in general are taller, albeit slimmer, less robust, and less productive. Except for the troublesome characteristic of dying after anthesis, male traits are favored for fiber production, in contrast to the situation for drug strains noted below. In former, labor-intensive times, the male plants were harvested earlier than the females, to produce superior fiber. The limited branching of fiber cultivars is often compensated for by possession of large leaves with wide leaflets, which obviously increase the photosynthetic ability of the plants. Since fiber plants have not generally been selected for narcotic purposes, the level of intoxicating constituents is usually limited.

An absence of such fiber-strain traits as tallness, limited branching, long internodes, and very hollow stems, is characteristic of narcotic strains. Drug forms have historically been grown in areas south of the north-temperate zone, often close to the equator, and are photoperiodically adapted to a long season. When grown in north-temperate climates maturation is much-delayed until late fall, or the plants succumb to cold weather before they are able to produce seeds. Unlike fiber strains that have been selected to grow well at extremely high densities, drug strains tend to be less persistent when grown in high concentration (de Meijer 1994). Drug strains can be very similar in appearance to fiber strains. However, a characteristic type of narcotic plant was selected in southern Asia, particularly in India and neighboring countries. This is dioecious, short (about a meter in height), highly branched, with large leaves (i.e. wide leaflets), and it is slow to mature. The appearance is rather like a short, conical Christmas tree.

Until recent times, the cultivation of hemp primarily as an oilseed was largely unknown, except in Russia. Today, it is difficult to reconstruct the type of plant that was grown there as an oilseed, because such cultivation has essentially been abandoned. Oilseed hemp cultivars in the modern sense were not available until very recently, but some land races certainly were grown specifically for seeds in Russia. Dewey (1914) gave the following information: “The short oil-seed hemp with slender stems, about 30 inches high, bearing compact clusters of seeds and maturing in 60 to 90 days, is of little value for fiber production, but the experimental plants, grown from seed imported from Russia, indicate that it may be valuable as an oil-seed crop to be harvested and threshed in the same manner as oil-seed flax.” Most hemp oilseed in Europe is currently obtained from so-called “dual usage” plants (employed for harvest of both stem fiber and seeds, from the same plants). Of the European dual-usage cultivars, ‘Uniko B’ and ‘Fasamo’ are particularly suited to being grown as oilseeds. Very recently, cultivars have been bred specifically for oilseed production. These include ‘Finola,’ formerly known as ‘Fin-314’ (Fig. 6) and ‘Anka’ (Fig. 7), which are relatively short, little-branched, mature early in north-temperate regions, and are ideal for high-density planting and harvest with conventional equipment. Dewey (1914) noted that a Turkish narcotic type of land race called “Smyrna” was commonly used in the early 20th century in the US to produce birdseed, because (like most narcotic types of Cannabis) it is densely branched, producing many flowers, hence seeds. While oilseed land races in northern Russia would have been short, early-maturing plants in view of the short growing season, in more southern areas oilseed landraces likely had moderate height, and were spaced more widely to allow abundant branching and seed production to develop. Until Canada replaced China in 1998 as a source of imported seeds for the US, most seeds used for various purposes in the US were sterilized and imported from China. Indeed, China remains the largest producer of hempseed. We have grown Chinese hemp land races, and these were short, branched, adapted to a very long growing season (i.e. they come into flower very slowly in response to photoperiodic induction of short days in the fall), and altogether they were rather reminiscent of Dewey’s description of Smyrna. Although similar in appearance to narcotic strains of C. sativa, the Chinese land races we grew were in fact low in intoxicating constituents, and it may well be that what Dewey thought was a narcotic strain was not. Although some forms of C. sativa have quite large seeds, until recently oilseed forms appear to have been mainly selected for a heavy yield of seeds, usually recognizable by abundant branching. Such forms are typically grown at lower densities than hemp grown only for fiber, as this promotes branching, although it should be understood that the genetic propensity for branching has been selected. Percentage or quality of oil in the seeds does not appear to have been important in the past, although selection for these traits is now being conducted. Most significantly, modern selection is occurring with regard to mechanized harvesting, particularly the ability to grow in high density as single-headed stalks with very short branches bearing considerable seed.

|  |

| Fig. 6. ‘Finola,’ the first cultivar of Cannabis sativa bred exclusively for grain. (Courtesy of the breeder, J.C. Callaway, Univ. Kuopio, Finland.) | Fig. 7. ‘Anka,’ the first registered North American bred cultivar of Cannabis sativa. This variety is best suited for grain production. (Courtesy of the breeder, P. Dragla, and of the Industrial Hemp Seed Development Company, Chatham, Ontario.) |

CONTROLLING THE DRUG ABUSE POTENTIAL OF HEMP

As detailed below, the development of hemp as a new legal crop in North America must be considered in relation to illicit cultivation, so it is important to appreciate the scope of the drug situation. Up until the first half of the 20th century, drug preparations of Cannabis were used predominantly as a recreational inebriant in poor countries and the lower socio-economic classes of developed nations. After World War II, marijuana became associated with the rise of a hedonistic, psychedelic ethos, first in the United States and eventually over much of the world, with the consequent development of a huge international illicit market that exceeds the value of the hemp market during its heyday. Table 3 shows the “economic significance” (dollars generated in the black market plus dollar cost of control measures) of the illicit drug industry associated with C. sativa, and contrasts this with the estimated dollar value of major categories of legitimate uses. In the Netherlands, the annual value of narcotic hemp cultivation (ca. $10 billion) exceeds the value of tulips (Collins 1999). Marijuana has become the most widely disseminated illicit species in the world (Schultes and Hofmann 1980). With the exception of alcohol, it is the most widely used recreational euphoric drug. About 25% of North Americans are believed to have used Cannabis illegally. According to the US National Institute on Drug Abuse (www.nida.nih.gov/Infofax/marijuana.html), more than 72 million Americans (33%) 12 years of age and older have tried marijuana. Cultivation, commerce, and consumption of drug preparations of Cannabis have been proscribed in most countries during the present century. The cost of enforcing the laws against Cannabis in North America is in the billions of dollars annually. In addition, there are substantial social costs, such as adverse effects on users, particularly those who are convicted. Tragically this includes some legitimate farmers who, faced with financial ruin because of the unprofitability of crops being grown, converted to growing marijuana.Table 3. Comparative annual world economic significance of categories of Cannabis activity.

| Category | World ($) | North America ($) | Type of investment |

| Recreational drugs | > 1 trillion | 100s of billions | Law enforcement, eradication, education |

| Industrial hemp | 100s of millionsz | 10s of millions | Production, development, marketing, research |

| Therapeutic drugs | 100s of millions | 10s of millions | Production, development, marketing, research |

| Phytoremediation | 10s of thousands | nil | Research |

| Ornamental hemp | thousands | nil | Development |

A rather thorough analysis of the scope of the illicit marijuana industry in Canada for 1998 is reported at www.rcmp-grc.gc.ca/html/drugsituation.htm#Marihuana and summarized in MacLeod (1999). At least 800 tonnes (t) of marijuana were grown in Canada in 1998, representing a harvest of 4.7 million flowering plants. More than 50% of the marijuana available in Canada is grown domestically. An average mature plant was estimated to produce 170 g of “marketable substance.” The value of the Canadian crop is uncertain, but has been estimated to be in the billions of dollars annually (Heading 1998; MacLeod 1999).

The US Drug Enforcement Administration’s online criminal justice statistics for 2000 (cscmosaic.albany.edu/sourcebook/1995/pdf/t440.pdf) shows the following seizures and eradication of plants of C. sativa: 40,929 outdoor plots (2,597,796 plants), 139,580,728 ditchweed (ruderal plants), 2,361 indoor operations (217,105 plants), for a grand total of 2,814, 903 plants destroyed. Impressively, the species was grown in all 50 states (including outdoor seizures in every state except Wyoming)! It is of course impossible to know exactly how much marijuana is cultivated in the United States, and perhaps only 10% to 20% of the amount grown is seized. The profitability of the illegal crop is indicated by a comparison of the cost of a bushel of corn (roughly $2.50) and a bushel of manicured marijuana (about $70,000; it has been suggested that prices range from $500 a pound, for low-quality marijuana, to more than $5,000 a pound for “boutique” strains like “Northern Lights” and “Afghan Kush”). According to a National Organization for the Reform of Marijuana Laws (NORML) (mir.drugtext.org/marijuananews/marijuana_ranks_fourth_largest_c.htm) marijuana is at least the fourth most valuable crop in America, outranked only by corn, soybeans, and hay. It was estimated that 8.7 million marijuana plants were harvested in 1997, worth $15.1 billion to growers and $25.2 billion on the retail market (the wholesale value was used to compare marijuana to other cash crops). Marijuana was judged to be the largest revenue producing crop in Alabama, California, Colorado, Hawaii, Kentucky, Maine, Rhode Island, Tennessee, Virginia, and West Virginia, and one of the top five cash crops in 29 other states.

Cannabis contains a seemingly unique class of chemicals, the cannabinoids, of which more than 60 have been described, but only a few are psychoactive. Cannabinoids are produced in specialized epidermal glands, which differ notably in distribution on different organs of the plant (high concentrations occur on the upper surface of the young leaves and young twigs, on the tepals, stamens, and especially on the perigonal bract). Given this distribution, the glands would seem to be protective of young and reproductive above-ground tissues (the roots lack glands). Two classes of epidermal glands occur—stalked and sessile (Fig. 8), but in either case the glandular cells are covered by a sheath under which resin is accumulated, until the sheath ruptures, releasing resin on the surface. The resin is a sticky mixture of cannabinoids and a variety of terpenes. The characteristic odor of the plant is due to the abundant terpenes, which are not psychoactive. The more important cannabinoids are shown in Fig. 9. In the plant the cannabinoids exist predominantly in the form of carboxylic acids, which decarboxylate with time or when heated. Delta-9-tetrahydrocannabinol (D9-THC, or simply THC) is the predominant psychoactive component. Other THC isomers also occur, particularly D8-THC, which is also psychoactive. Technically, the euphoric psychological effects of THC are best described by the word psychotomimetic. Cannabidiol (CBD) is the chief non-psychotomimetic cannabinoid. A THC concentration in marijuana of approximately 0.9% has been suggested as a practical minimum level to achieve the (illegal) intoxicant effect, but CBD (the predominant cannabinoid of fiber and oilseed varieties) antagonizes (i.e. reduces) the effects of THC (Grotenhermen and Karus 1998). Concentrations of 0.3% to 0.9% are considered to have “only a small drug potential” (Grotenhermen and Karus 1998). Some cannabinoid races have been described, notably containing cannabichromene (particularly in high-THC forms) and cannabigerol monomethyl ether (in some Asian strains). The biosynthetic pathways of the cannabinoids are not yet satisfactorily elucidated, although the scheme shown in Fig. 10 is commonly accepted. At least in some strains, THC is derived from cannabigerol, while in others it may be derived from CBD. CBN and D8-THC are considered to be degradation products or analytical artifacts (Pate 1998a).

|  |

| Fig. 8. Scanning electron micrographs of the abaxial surface of a perigonal bract (which envelops the fruit). These bracts are the most intoxicating part of the plant, and may contain 20% THC, dry weight. The resin is synthesized both in stalked and sessile glands. Multicellular secretory glands (of phallic appearance), some broken stalks of these (note cellular appearance), and unicellular cystolith hairs (claw-like structures) are pictured. | Fig. 9. Some important cannabinoids of cannabis resin. D9-THC (delta-9 tetrahydrocannabinol) is the chief intoxicant chemical and predominates in intoxicant strains, while the isomer D8-THC is usually present in no more than trace amounts. CBD (cannabidiol) is the chief non-intoxicant chemical, and predominates in non-intoxicant strains; it has sedative effects. The non-intoxicant CBN (cannabinol) is a frequent degradation or oxidation product. The non-intoxicant cannabichromene (CBC) is typically found in trace amounts in intoxicant strains. The non-intoxicant cannabigerol (CBG) is considered to be a precursor of the other cannbinoids (see Fig. 10). |

Fig. 10. Proposed biosynthetic pathways of the principal cannabinoids (after Pate 1998b).

Both in Canada and the US, the most critical problem to be addressed for commercial exploitation of C. sativa is the possible unauthorized drug use of the plant. Indeed, the reason hemp cultivation was made illegal in North America was concern that the hemp crop was a drug menace. The drug potential is, for practical purposes, measured by the presence of THC. THC is the world’s most popular illicit chemical, and indeed the fourth most popular recreational drug, after caffeine, alcohol, and nicotine. “Industrial hemp” is a phrase that has become common to designate hemp used for commercial non-intoxicant purposes. Small and Cronquist (1976) split C. sativa into two subspecies: C. sativa subsp. sativa, with less than 0.3% (dry weight) of THC in the upper (reproductive) part of the plant, and C. sativa subsp. indica (Lam.) E. Small & Cronq. with more than 0.3% THC. This classification has since been adopted in the European Community, Canada, and parts of Australia as a dividing line between cultivars that can be legally cultivated under license and forms that are considered to have too high a drug potential. For a period, 0.3% was also the allowable THC content limit for cultivation of hemp in the Soviet Union. In the US, Drug Enforcement Agency guidelines issued Dec. 7, 1999 expressly allowed products with a THC content of less than 0.3% to enter the US without a license; but subsequently permissible levels have been a source of continuing contention. Marijuana in the illicit market typically has a THC content of 5% to 10% (levels as high as 25% have been reported), and as a point of interest, a current Canadian government experimental medicinal marijuana production contract calls for the production of 6% marijuana. As noted above, a level of about 1% THC is considered the threshold for marijuana to have intoxicating potential, so the 0.3% level is conservative, and some countries (e.g. parts of Australia, Switzerland) have permitted the cultivation of cultivars with higher levels. It should be appreciated that there is considerable variation in THC content in different parts of the plant. THC content increases in the following order: achenes (excluding bracts), roots, large stems, smaller stems, older and larger leaves, younger and smaller leaves, flowers, perigonal bracts covering both the female flowers and fruits. It is well known in the illicit trade how to screen off the more potent fractions of the plant in order to increase THC levels in resultant drug products. Nevertheless, a level of 0.3% THC in the flowering parts of the plant is reflective of material that is too low in intoxicant potential to actually be used practically for illicit production of marijuana or other types of cannabis drugs. Below, the problem of permissible levels of THC in food products made from hempseed is discussed.

There is a general inverse relationship in the resin of Cannabis between the amounts of THC present and the amount of the other principal cannabinoid, CBD. Whereas most drug strains contain primarily THC and little or no CBD, fiber and oilseed strains primarily contain CBD and very little THC. CBD can be converted to THC by acid catalyzed cyclization, and so could serve as a starting material for manufacturing THC. In theory, therefore, low-THC cultivars do not completely solve the problem of drug abuse potential. In practice, however, the illicit drug trade has access to easier methods of synthesizing THC or its analogues than by first extracting CBD from non-drug hemp strains.

Breeding for low THC cultivars in Europe has been reviewed by Bócsa (1998), Bócsa and Karus (1998), and Virovets (1996). Some researchers have claimed to have produced essentially THC-free strains, although at present no commercial cultivar seems to be 100% free of THC. THC content has proven to be more easily reduced in monoecious than in dioecious varieties. It should be possible to select THC-free strains, and there has been speculation that genetic engineering could be helpful in this regard. As a strategic economic and political tactic, France has been attempting for several years to have the European Union (EU) adopt legislation forbidding the cultivation of industrial hemp cultivars with more than 0.1% THC, which would mean that primarily French varieties would have to be cultivated in Europe. However, the Canadian government has found that some French material has proven to be excessively high in THC.

There is certainly a need to utilize available germplasm sources in order to breed suitable cultivars for North America. A list of the 24 approved cultivars for the 2001 season in Canada is at www.hc-sc.gc.ca/hpb-dgps/therapeut/htmleng/hemp.html. Most of these are regulated by the European Organization of Economic Cooperation and Development (OECD). These cultivars are “approved” for use in Canada not on agricultural criteria, but merely on the basis that they meet the THC criterion. Indeed, most of these are unsuitable or only marginally suitable for Canada (Small and Marcus 2000), and only a very few Canadian cultivars to date have been created. In Canada, every acquisition of hemp grown at a particular place and time must be tested for THC content by an independent laboratory and, under the industrial hemp regulations, fields of hemp with more than 0.3% THC may require destruction (a slight degree of flexibility is generally exercised). Importation of experimental hemp lines (i.e. other than the approved cultivars) requires importation licenses (as well as phytosanitary clearance of the shipment by the Canadian Food Inspection Agency), and the importation licenses require an indication that the THC contents are low.

In Canada, the methodology used for analyses and sample collection for THC analysis of hemp plantings is standardized (at the Health Canada/Therapeutics Program/Hemp web site at www.hc-sc.gc.ca/hpb-dgps/therapeut/htmleng/hemp.html, see “Industrial Hemp Technical Manual” for procedures on sampling plant materials and chemical procedures for determining THC levels). The regulations require that one of the dozen independent laboratories licensed for the purpose conduct the analyses and report the results to Health Canada. Sample collection is also normally carried out by an independent authorized firm. The Canadian system of monitoring THC content has rigidly limited hemp cultivation to cultivars that consistently develop THC levels below 0.3%.

Because C. sativa has been a neglected crop for so long in North America, there are only negligible genetic resources available on this continent. Most germplasm stocks of hemp are in Europe, and the largest and most important collection is the Vavilov Institute gene bank in Leningrad. Figure 11 shows THC concentrations in the Vavilov collection, as well as in our own collection, largely of European germplasm. A disturbingly high percentage of the collections have THC levels higher than 0.3%, making it difficult to incorporate these into breeding programs.

Fig. 11. Frequency histograms of THC concentration in germplasm collections. Left, collection of E. Small and D. Marcus; of the 167 accessions, 43% had THC levels >0.3%. Right, the collection of the Vavilov Institute, St. Petersburg; of the 278 accessions for which chemical analyses were reported in Anonymous (1975), about 55% had THC levels >0.3%.

Soil characteristics, latitude and climatic stresses have been found to have significant effects on THC concentrations, and there are seasonal and even diurnal variations (Small 1979; Pate 1998b). However, the range of THC concentrations developed by low-THC cultivars (those typically with £0.3% THC) under different circumstances on the whole is limited, for the most part generally not varying more than 0.2 percentage points when grown in a range of circumstances, and usually less (note information in Scheifle et al. 1999; Scheifle 2000, Scheifle and Dragla 2000). Practically, this has meant in Canadian experience that a few cultivars have been eliminated from further commercial cultivation because they sometimes exceed the 0.3% level (‘Fedora 19’ and ‘Futura,’ authorized in 2000, have now been removed because some test results in several years exceeded 0.3%; ‘Finola’ and ‘Uniko B’ are under probation because of elevated levels), but on the whole most of the permitted cultivars have maintained highly consistent development of quite low levels of THC.